SDBC 10-pack GSP Bassoon Cane

10-pack Gouged, Shaped, and Profiled Bassoon Cane. Professionally gouged, shaped, and profiled bassoon cane processed using high quality cane. Manufactured on a Greg James Precision Music Products gouger, Pfeifer profiler, and original shapers.

Customization order form prompted when item is added to cart.

Features

Select reed strengths, popular reed shapes, and profiles

10-pack Gouged, Shaped, and Profiled Bassoon Cane. Professionally gouged, shaped, and profiled bassoon cane processed using high quality cane. Manufactured on a Greg James Precision Music Products gouger, Pfeifer profiler, and original shapers.

Customization order form prompted when item is added to cart.

Features

Select reed strengths, popular reed shapes, and profiles

10-pack Gouged, Shaped, and Profiled Bassoon Cane. Professionally gouged, shaped, and profiled bassoon cane processed using high quality cane. Manufactured on a Greg James Precision Music Products gouger, Pfeifer profiler, and original shapers.

Customization order form prompted when item is added to cart.

Features

Select reed strengths, popular reed shapes, and profiles

Dimensions

Length: 120mm

Gouge Dimensions: 1.35mm / -0.10mm eccentricity

Select Reed Strengths: Medium-Soft, Medium, Medium-Hard

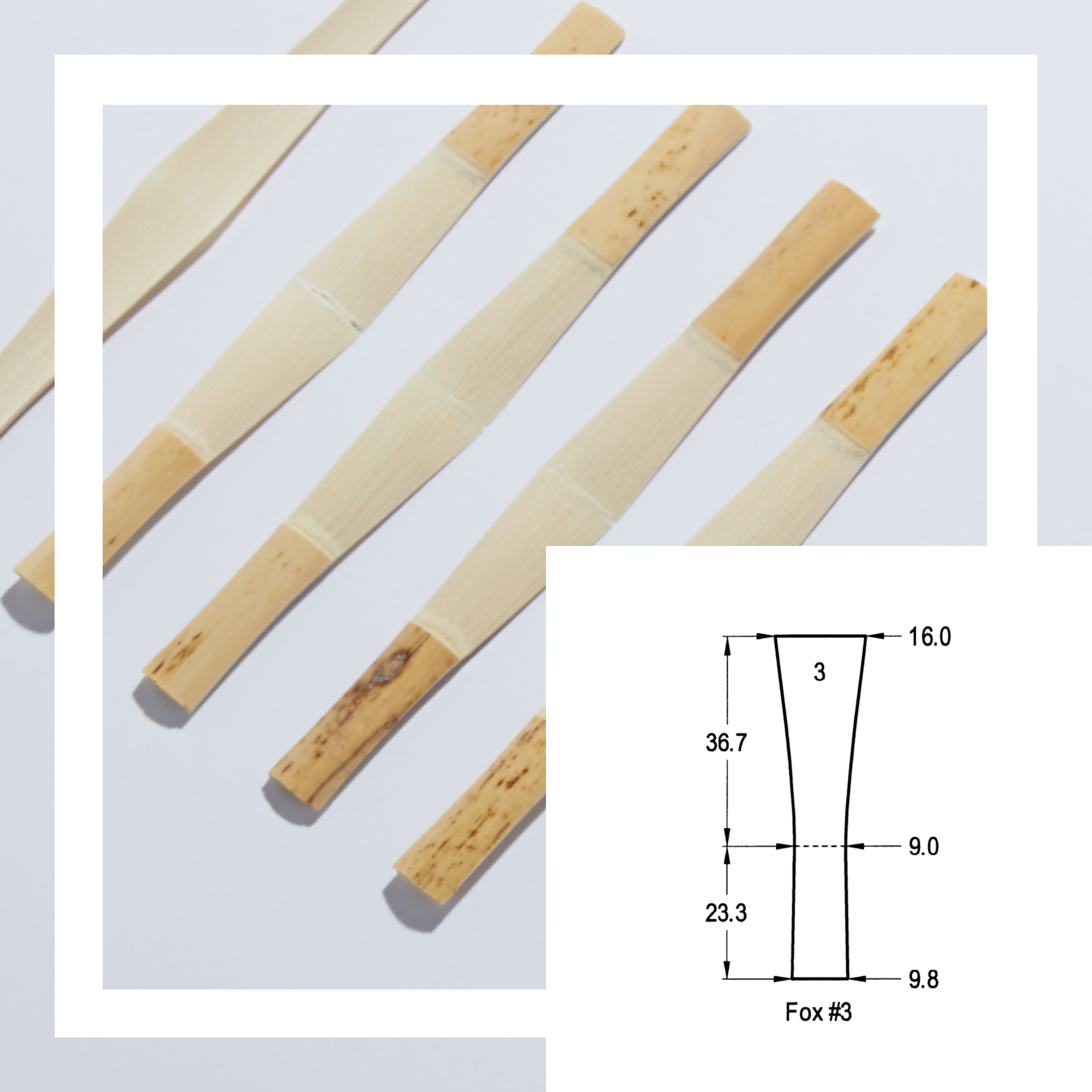

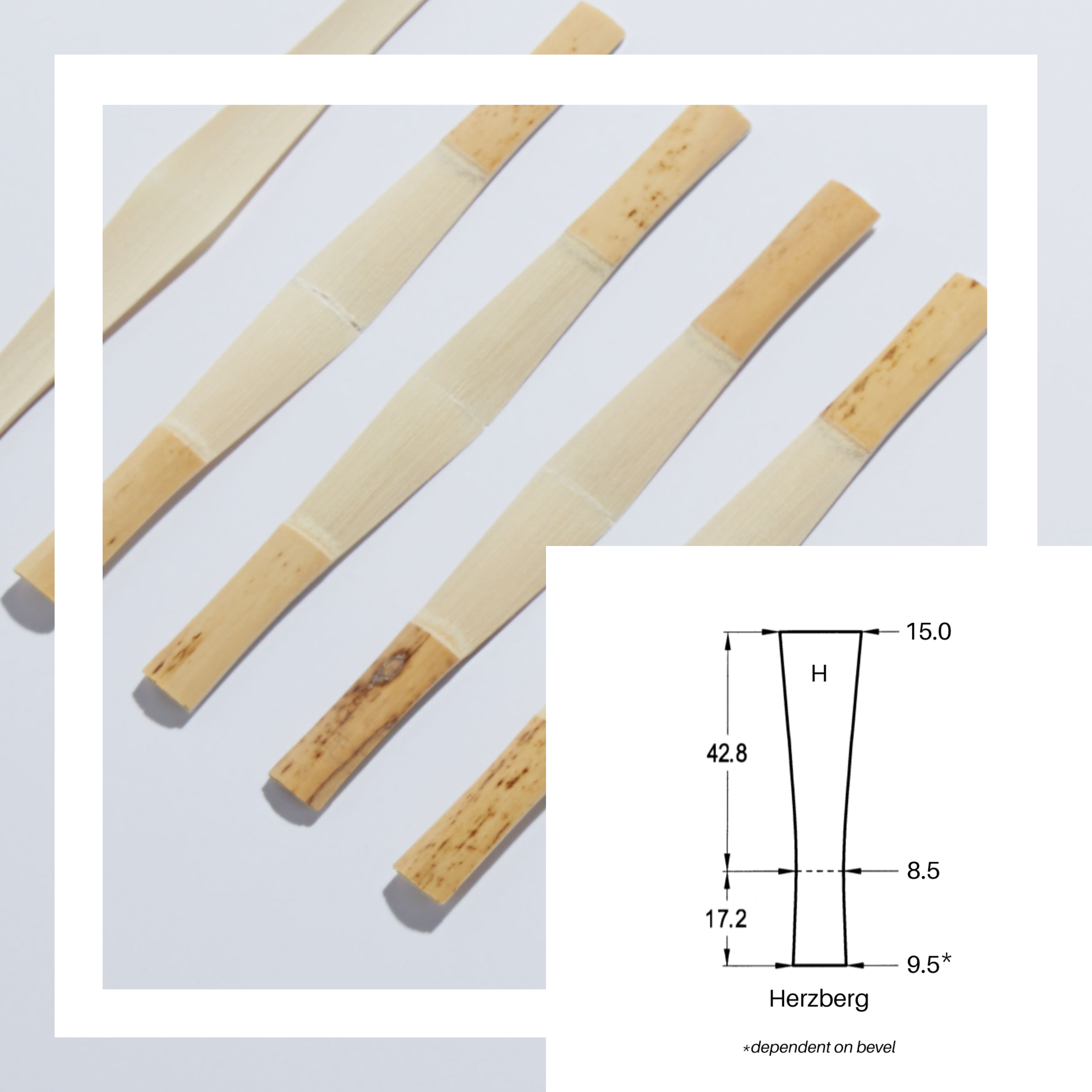

Select Reed Shapes: Blain, Fox 1, Fox 2, Fox 3, Herzberg, Knockenhauer, Rieger 1A, Rieger 2, Rieger 6

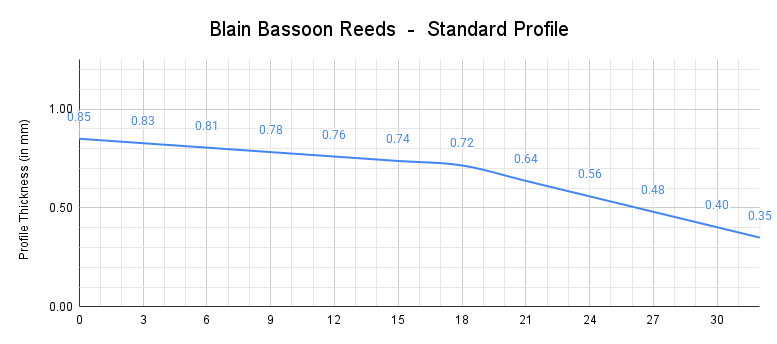

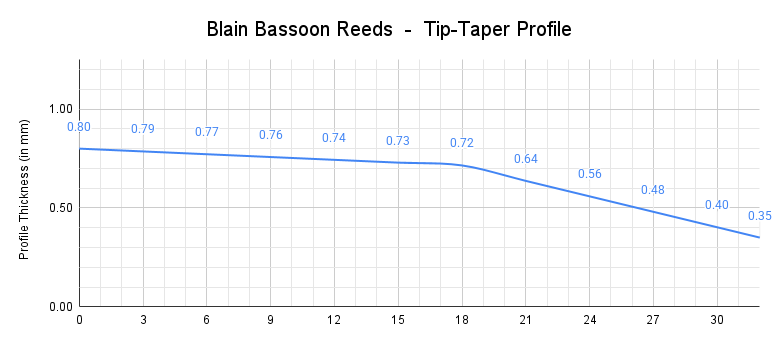

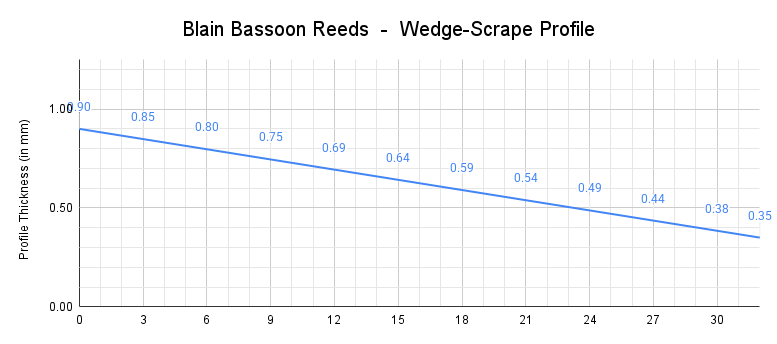

Select Reed Profiles: Standard, Tip-Tapered, Wedge Scrape

Processed from 24mm-25mm diameter high-quality Rigotti bassoon tube cane from Var, France

Cane Source

Rigotti, Cogolin, Var Department, France.

Bassoon cane from the Var region of France carries the distinct character of its terroir—where climate, soil, and expert cultivation come together to create something truly exceptional. Grown in the sun-drenched fields of Provence, the Mistral winds from the Mediterranean play a crucial role in its cultivation, Rigotti cane develops a rich, complex structure, offering the perfect balance of strength and flexibility. Each tube of Rigotti cane is then carefully harvested, aged, and processed to bring out its full potential. The result? A reed that responds with depth, nuance, and clarity—allowing bassoonists to craft reeds that sing with warmth, clarity, and a beautiful timbre. For those who appreciate the finest materials for their artistry, Rigotti bassoon cane is the grand cru of reed making.

The Process

The tube cane is received directly from Rigotti and rests for 24-48 hours, it is then split and cut into segments. The segments are stored for up to an additional 6 months before being processed using Louis Skinner’s methods. The cane is processed on very precise machinery made by Greg James of Precision Music Products Ltd. These tools are so precise that after the cane has been pre-gouged, the Bulk density of the splits can be measured and the cane is presorted before continuing to the gouging process. The Precision Music Products Ltd., Gouger itself is a side-edge clamping double radius gouger that is set to the requested gouge thickness and eccentricity specifications. Note: we retool the machines with specific custom-made blades to the user selection of an eccentric or concentric gouge. This means, the gouge is a true concentric or eccentric gouge. The cane is then hardness tested using a Potratz Hardness Tester and must fall within a specific range of usability.

Qualitative Testing and Evaluation

The qualitative tests of Bulk density and hardness are conducted in the ‘tradition’ of bassoon reed making, so users can associate the material properties with accepted evaluation techniques within the bassoon reed making community. In addition to these ‘traditional’ measurements, a nondestructive ultrasonic evaluation (NDE), more suited for aerospace materials science, is conducted on the cane splits determining the Stiffness (E) and Resiliency (Z).

This scientific approach evaluates the material properties of reed cane that impact musical performance. Through isolating the material properties in a double blind evaluation (as part of my DMA research project), the performance characteristics of the reed cane in a musical setting became more evident. The following trends were observed: 1. high material stiffness requires a thinner gouge, 2. relatively lower impedance equates to a free-blowing reed, 3. higher density means a brighter tone and more complexity of timbre as observed on an oscilloscope, and 4. Specific Stiffness was observed to correlate with the tonal characteristics and resistance of a reed.

From this research a multi-attribute evaluation function was developed and has the highest correspondence to successful yield in comparison to the accepted ‘traditional’ reed making evaluations. As the material properties deviate farther from these calculated ranges, the reed becomes more unstable and cane splits deviating more than +/- 40% from the accepted ranges, in any regard, have the lowest potential of becoming a successful reed.